Temporary noise barriers, also known as noise curtains, noise mats or acoustic barriers are products that can be deployed across a number of industries and applications to reduce excess noise created by a wide variety of sources.

Temporary Noise Barriers are commonly used in markets with advanced health and safety practices and systems. Health and safety today treats noise as a hazard or risk and a temporary noise barrier can manage and mitigate a noise hazard by lowering the decibels created by the source.

In Australia, we have seen an increase in constructors and contractors managing safety-related noise issues with Temporary Noise Barriers particularly when their work interfaces with the public. Examples of this include concrete cutters or rock breakers in close proximity to pedestrians. Building sites with high levels of cumulative noise in condensed urban areas are also employing noise curtains to meet their consent requirements, particularly in Auckland under the unitary plan. The common strategy across larges sites is to treat an individual noise source with a screen or enclosure.

What are noise barriers made of?

Noise barriers generally have a front panel made from PVC, covering an acoustic absorbent, enclosed on the absorbent side with different materials from just a gauze, to more complex and durable layers. This is the side that faces the noise source. Most barriers on the market are generally just over 2m high, and around 1.3m wide.

The weight of acoustic barriers varies widely, and this area is somewhat of a red herring. A heavier barrier is not a good indicator of the barrier’s ability to absorb or insulate noise.

How effective is a temporary noise barrier?

Noise barriers in the Australia market

There are many barriers on the market that make claims on what their barriers can achieve in terms of absorption or insulation. This can be confusing as a consumer of the product when you are looking to create a real solution to your noise issue. There is however an easy solution to this. Any reputable acoustic barrier manufacturer will be able to provide you with laboratory testing from independently registered organisations. These are generally Universities with the necessary facilities to carry out such tests. It is important to note that endorsements from Consumer bodies are not a reflection on any of the technical aspects of a product. These are simply subscription-based memberships which in no way vet any of the products they endorse from technical aspects.

When using noise barriers, it is important that the full pedigree of all aspects of the product is also taken into consideration. While the noise attenuation properties are of paramount importance, factors such as fire rating, waterproof capabilities, tensile testing, weatherproof are critical when barriers are to be deployed on any site. Once again, all of these aspects of the barrier need to be endorsed by independent lab tests. What is of critical importance is that the lab tests are for the complete noise barrier, not just for a single component of the barrier. Many barrier manufacturers will try and present a report for a single component of the barrier and try to justify that the complete product will behave the same way. Again, with all these aspects, to test the true pedigree of any noise barrier (or any other product) simply ask the supplier for an independent lab test to back up any claims made in their marketing material.

Noise Barriers such as Echo Barriers are used to screen noise and filter noise energy from the environment. Echo Barrier is the world standard in temporary noise mitigation and is widely used across the globe in construction, manufacturing and various other applications. The barrier is made of only the highest quality materials. Echo Barrier is the highest performing noise barrier on the Australia market in terms of noise attenuation, backed up by independent lab reports. The Echo Barrier is unique in that the acoustic infill is held within a waterproof membrane that allows noise energy to be absorbed, whilst keeping the barrier dry.

Weighing in between 6-7kg per barrier, there is no other barrier that can compete with the Echo Barrier in terms of attenuation to weight. A critical factor when barriers are moved around on site, and placing adding strain on fence lines.

Up to 40dB noise control

Echo Barrier is a cutting-edge acoustic barrier used worldwide, tested and proven to give up to 40dB noise control.

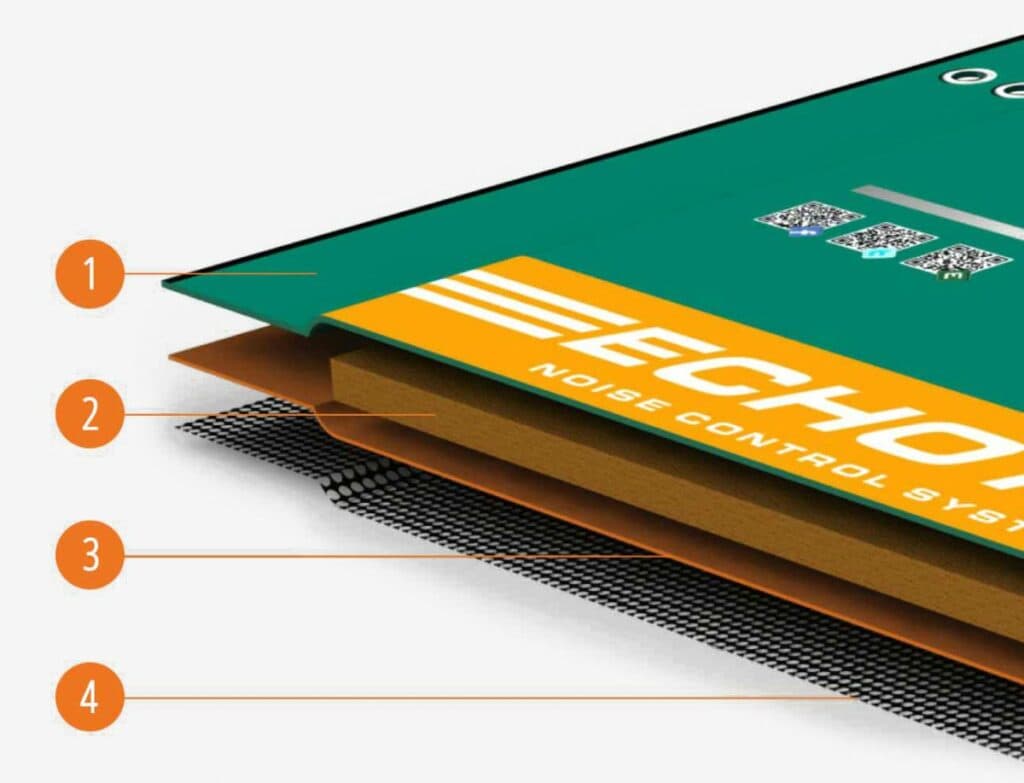

1. WATERPROOF OUTER LAYER

Extremely durable and waterproof, the highest quality PVC makes our acoustic barrier easy to clean and professional looking.

2. ACOUSTIC ABSORBENT

Top grade lightweight acoustic absorbent which prevents sound from reflecting off the barrier.

3. WATERPROOF BREATHABLE MEMBRANE

Allows sound to be absorbed but keeps water out.

4. DURABLE REINFORCED MESH

Extends product life to retain acoustic performance in harsh working environments.

Echo barrier h series noise control system

Dimensions (flat): 2050mm high x 1335mm wide

Dimensions (rolled): 400mm diameter x 1335mm

Weight: 6kg

Field Performance: 10–40 dB Noise Reduction (greater if barriers are doubled up)